IN625 nikel Base alloy Bubuk Inconel 625 bubuk

Panjelasan Produk

Huarui suhu luhur alloy basis nikel IN625 bubuk mangrupa bubuk dioptimalkeun, utamana cocog pikeun SLM ngabentuk téhnologi, kaasup EOS Selektif Laser Lebur Equipment (EOSINT M Series), Konsep Laser Lebur Equipment, Renishaw Laser Lebur Equipment, Amérika 3D Systems Laser Equipment, jeung institutes panalungtikan domestik jeung institutes.

Ngaliwatan distribusi ukuran partikel béda, éta ogé bisa dibagi kana suntik molding bubuk, laser cladding bubuk, nyemprot bubuk, panas isostatic mencét bubuk jeung saterusna.

Spésifikasi

| Komposisi Kimia (%) tina Inconel 625 Bubuk | ||||||

| Cr | Co | Al | Mo | Mn | Ti | Nb |

| 20-23 | ≤1.0 | ≤0.4 | 8.0-10 | ≤0.5 | ≤0.4 | 3.15-4.15 |

| Fe | C | Si | P | S | O | Ni |

| ≤0.5 | ≤0.1 | ≤0.5 | ≤0,015 | ≤0.15 | ≤0.02 | Bal |

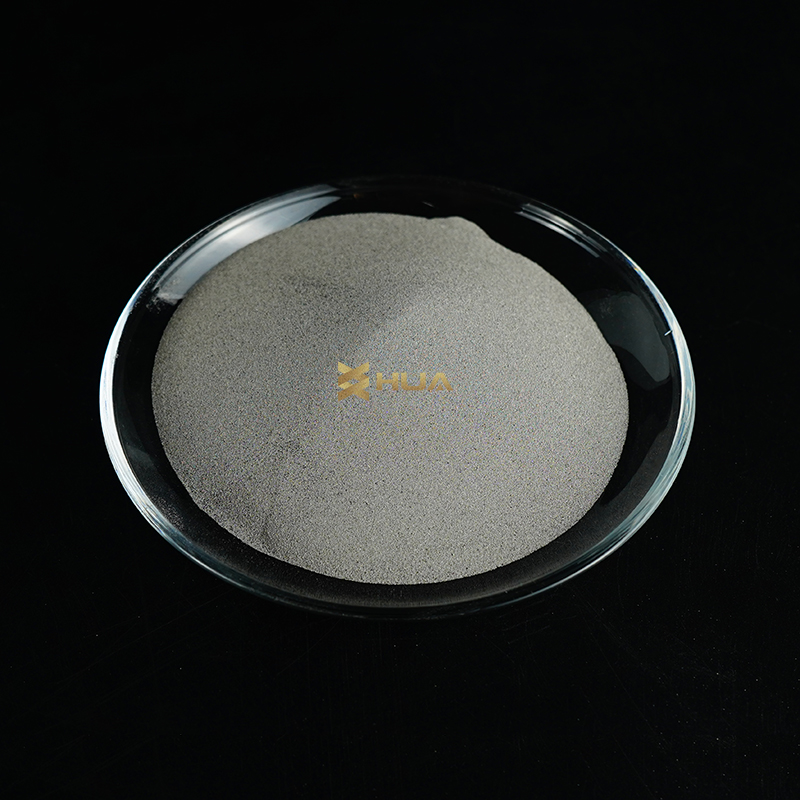

| Kapadetan katempo: 4,50g / cm3 | Warna: kulawu | Wangun: buleud | ||||

| Ukuran partikel | 15-53 mikron;45-105 mikron;45-150 mikron | |||||

| Inconel 625 Bubuk Pasipatan | ||||||

| Rentang Ukuran | 0~25um | 0~45um | 15~45um | 45~105um | 75~180um | |

| Morfologi | Bulat | Bulat | Bulat | Bulat | Bulat | |

| Distribusi Ukuran Partikel | D10: 6 emh | D10: 9 emh | D10: 14um | D10: 53um | D10: 78um | |

| D50:16um | D50: 28um | D50: 35um | D50: 69 emh | D50: 120um | ||

| D90: 23um | D90: 39 emh | D90: 45um | D90: 95um | D90: 165um | ||

| Kamampuh aliran | N/A | ≤30S | ≤28S | ≤16S | ≤18S | |

| Kapadetan semu | 4.2g/cm3 | 4,5 g/cm3 | 4,4 g/cm3 | 4,5 g/cm3 | 4,4 g/cm3 | |

| Kandungan Oksigén (wt%) | O: 0.06 ~ 0.018wt%, standar ASTM: ≤0.02 wt% | |||||

| 3D percetakan Gas Atomized Inconel 625 Bubuk kalawan harga pangalusna | ||||||

| (oksigén low, sphericity tinggi jeung fluidity alus) | ||||||

Aplikasi

1. HVOF

2. Plasma palapis

3. percetakan 3D / manufaktur aditif

4. las bubuk

5. logam suntik molding

6. isostatic panas

Produk patali

Urang ogé nyadiakeun bubuk Inconel 718, bubuk NiCr, bubuk NiAl, bubuk Ni20-Ni65, wilujeng sumping ka panalungtikan!