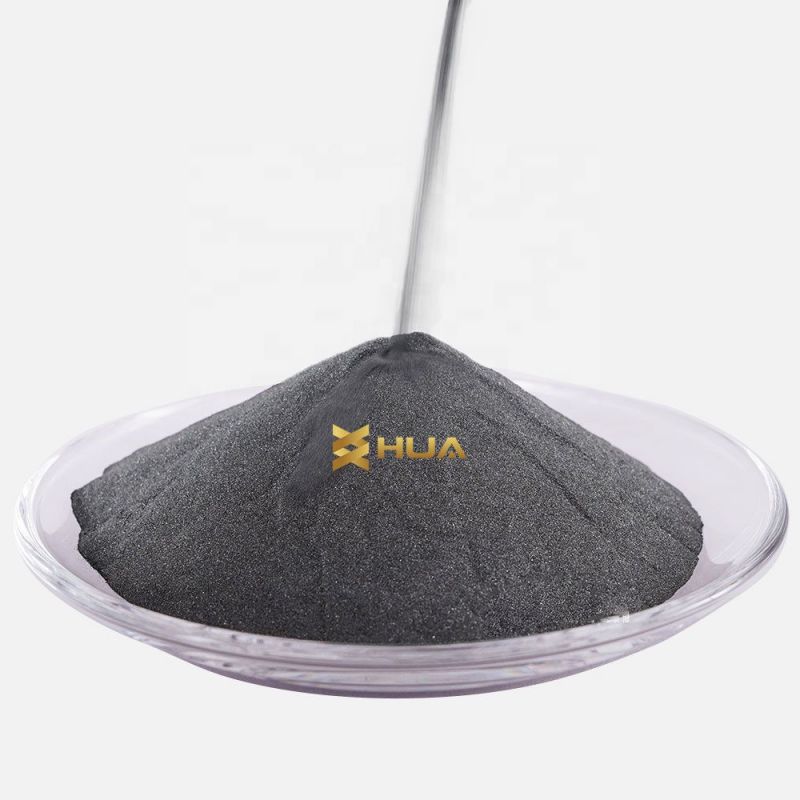

Logam alloy titanium bubuk ti6al4v bubuk pikeun percetakan 3d

Panjelasan Produk

Ti6Al4V bubuk disebut TC4, mangrupa α-β titanium alloy kalawan rasio kakuatan-to-beurat tinggi na lalawanan korosi alus teuing.Ieu salah sahiji alloy titanium paling ilahar dipake tur loba dipaké dina dénsitas lemah sareng lalawanan korosi alus teuing diperlukeun pikeun industri aerospace misalna jeung aplikasi biomechanical (implants na prostheses).Ti6Al4V umumna dianggap "dasar" industri titanium. sabab ku jauh titanium alloy paling loba dipaké, leuwih ti 50% tina jumlah total titanium.

TC4 alloy titanium boga lalawanan korosi alus teuing.Cai mibanda runtuyan kaunggulan kayaning dénsitas low, kakuatan husus tinggi, kateguhan alus, weldability alus jeung saterusna.Geus dipaké dina aerospace, pétrokimia, shipbuilding, mobil, farmasi jeung industri lianna.

Rincian spésifikasi

| Komposisi bubuk titanium nitrida | |||

| Barang | TiN-1 | TiN-2 | TiN-3 |

| Kasucian | >99.0 | >99.5 | >99.9 |

| N | 20.5 | > 21.5 | 17.5 |

| C | <0.1 | <0.1 | 0.09 |

| O | <0.8 | <0.5 | 0.3 |

| Fe | 0.35 | <0.2 | 0.25 |

| Kapadetan | 5,4 g/cm3 | 5,4 g/cm3 | 5,4 g/cm3 |

| ukuran | <1 mikron 1-3 mikron | ||

| 3-5 mikron 45 mikron | |||

| ékspansi termal | (10-6K-1): 9,4 poék / bubuk konéng | ||

Spésifikasi

| Titanium alloy aluminium (TC4) bubuk Pasipatan | |||||

| Rentang Ukuran | 0-25um | 0-45um | 15-45um | 45-105um | 75-180um |

| Morfologi | Bulat | Bulat | Bulat | Bulat | Bulat |

| PSD-D10 | 7 emh | 15 emh | 20 emh | 53 emh | 80 emh |

| PSD-D50 | 15 emh | 34 emh | 35 emh | 72 emh | 125um |

| PSD-D90 | 24 emh | 48 emh | 50 emh | 105um | 200um |

| Kamampuh aliran | N/A | ≤120S | ≤50S | ≤25S | 23S |

| Kapadetan semu | 2,10 g/cm3 | 2,55g/cm3 | 2,53g/cm3 | 2,56g/cm3 | 2,80 g/cm3 |

| Kandungan Oksigén (wt%) | O: 0.07-0.11wt%, standar ASTM: ≤0.13wt% | ||||

Urang nawiskeun ogé jasa ngaropéa

Welcom mun merlukeun COA & sampel bébas pikeun Test

SEM

| Titanium alloy aluminium (TC4) bubuk Unsur utama: | ||

| Al | V | Ti |

| 5.50-6.75 | 3.50-4.50 | Bal |

Aplikasi

1. laser / éléktron beam manufaktur tambahan (SLM / EBM).

2. bubuk metallurgy (PM) jeung prosés lianna.

3. rupa-rupa printer logam 3D, kaasup Renishaw, Renishaw, Jérman EOS (seri EOSINT M), Konsep laser, sistem 3D jeung alat lebur laser séjén.

4. pabrik bagian aerospace, Aeroengine wilah jeung bagian séjén karya perbaikan.

5. alat médis.